Mold Manufacturing

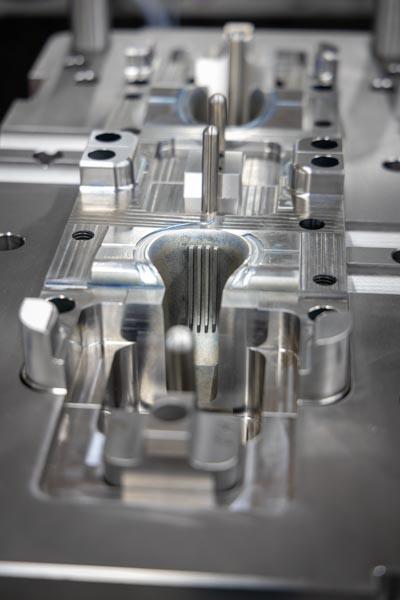

At Liberty Molds, we specialize in the manufacture of plastic injection molds for the automotive, medical, and consumer goods industries, and for presses up to 500-ton capacity. Our solid reputation for quality means your mold will work right the very first time – and through thousands of cycles.

Our process begins with client collaboration. Our designers meet with your engineering team early on to ensure a sound design and a tool you can count on. We plan for your success.

From there, our team of mold makers executes the plan, integrating their wealth of knowledge with the latest machine and computer technology. We employ high-speed and 5-axis milling technology, robotic part and tool changers, cutting-edge EDM machines and more -- all working in harmony to efficiently build your mold.

Plastic Injection Molds for the Automotive Industry

Today’s automotive industry relies on injection-molded plastic parts to maintain its competitive edge. Improving safety, increasing fuel efficiency and reducing environmental impact have all become priorities for automakers. And injection-molded plastic parts are an essential component in achieving these goals.

Lighter-weight materials are key to improving fuel economy, which is why metal parts are now being replaced by plastic. But lightening the load also means that vehicle manufacturers can incorporate advanced safety devices, electronic systems and emission control devices. And all of these devises are also primarily composed of plastic.

If we take a look at electric vehicles, for instance, we see that weight offset results in improved system efficiency as well as consistency when operating in the all-electric mode. On the other hand, fuel-based cars and trucks also rely on injection-molded plastic parts to reduce carbon emissions and comply with increasingly stringent government regulations.

Automotive OEMs have embraced this metal-to-plastic conversion as a proven method to increase fuel efficiency by reducing vehicle weight Replacing heavier metal parts with identical lighter-weight (and equally durable) plastic components, manufacturers can meet all their environmental and operational efficiency goals.

Vehicle manufacturers rely on the ultra-precise plastic injection molds built by Liberty Molds in order to produce a vast array of automotive parts, including: 5-axis machining helps speed milling operations by minimizing setups.

5-axis machining helps speed milling operations by minimizing setups.

- Instrument Panel Components

- Register Assemblies

- Interior Trim Plates & Bezels

- Cup Holders & Slide-Out Trays

- Shifter Knobs & Assemblies

- Keyless Entry Housings

- Back Lighting Controls & Buttons

- Locks & Switches

- Door Handle Components

- Sunroof Components & Assemblies

- DVD Housings

Plastic Injection Molds for the Consumer Goods Industry

The simple items we use every day to make our lives easier are created by the consumer goods industry. These items must be attractive as well as functional. And they must be manufactured quickly, affordably and sustainably.

The traditional materials of metal, wood and glass are quickly being replaced by high-quality plastic in the production of these consumer goods. And innovative processes and technologies, such as overmolding and insert molding, are increasingly being utilized.

Overmolding uses a combination of two or more different materials to create a single part. During the manufacturing process, one material will partially or fully cover the other material (for example, plastic over metal or rubber over plastic).

Our EDM cell includes two ultra-precision Agie Charmilles EDM served by a System 3R robotic electrode and part changer for round-the-clock productivity.Insert molding, on the other hand, involves injecting plastic into a mold that contains a pre-placed insert. The insert can be composed of either metal or different types of plastic. The end result is a single molded piece, with an insert surrounded by the plastic. A good example of insert molding is an electronics manufacturer who inserts small metal connectors, mounts, or fine threads into plastic parts during the mold process.

Our EDM cell includes two ultra-precision Agie Charmilles EDM served by a System 3R robotic electrode and part changer for round-the-clock productivity.Insert molding, on the other hand, involves injecting plastic into a mold that contains a pre-placed insert. The insert can be composed of either metal or different types of plastic. The end result is a single molded piece, with an insert surrounded by the plastic. A good example of insert molding is an electronics manufacturer who inserts small metal connectors, mounts, or fine threads into plastic parts during the mold process.

Other types of consumer goods that are produced with plastic injection molds include:

- Housewares

- Personal hygiene products

- Convenience products

- Cosmetics products

Prototype Plastic Injection Molding

Prototype molds are produced with the shape and functionality that’s needed to adequately test the mold’s form, fit and performance. But they lack the fine details (such as surface finish or color preference) of the production mold. Prototypes can be built quickly, and are not intended for long-term use.

Why a prototype mold?

Liberty Molds Workforce Development includes apprenticeship and hands-on mentoring.Do you need to evaluate a mold -- cost-effectively and efficiently -- before you commit to the final product? Then you want a prototype mold. Or maybe you’re unsure of how your final product should look, or the best way to meet specifications. In those situations, an injection mold prototype is the way to go. It’s a quick and inexpensive way to help identify what works and what needs to be changed.

Liberty Molds Workforce Development includes apprenticeship and hands-on mentoring.Do you need to evaluate a mold -- cost-effectively and efficiently -- before you commit to the final product? Then you want a prototype mold. Or maybe you’re unsure of how your final product should look, or the best way to meet specifications. In those situations, an injection mold prototype is the way to go. It’s a quick and inexpensive way to help identify what works and what needs to be changed.

Whatever your needs, the Liberty mold making team is ready, willing and able to tackle your next project, and create an exceptional, ultra-precise tool that will exceed your expectations. Our team combines seasoned veterans with young apprentices to build our workforce with the best balance of drive, talent, and enthusiasm for the consistent growth we have experienced.