Quality and Inspection

At Liberty Molds, we’re serious about quality. Which is why we use the most advanced analysis and inspection technologies -- so you can produce perfect parts every time.

At Liberty Molds, we’re serious about quality. Which is why we use the most advanced analysis and inspection technologies -- so you can produce perfect parts every time.

From conception through completion, world-class quality is evident in every plastic injection mold we build. We consistently exceed our customers’ expectations, because our culture is based upon open communication with them. And our quality management system is continually reviewed for process improvement. We can ensure delivery of a superior product to every one of our customers, every time.

Quality Assurance

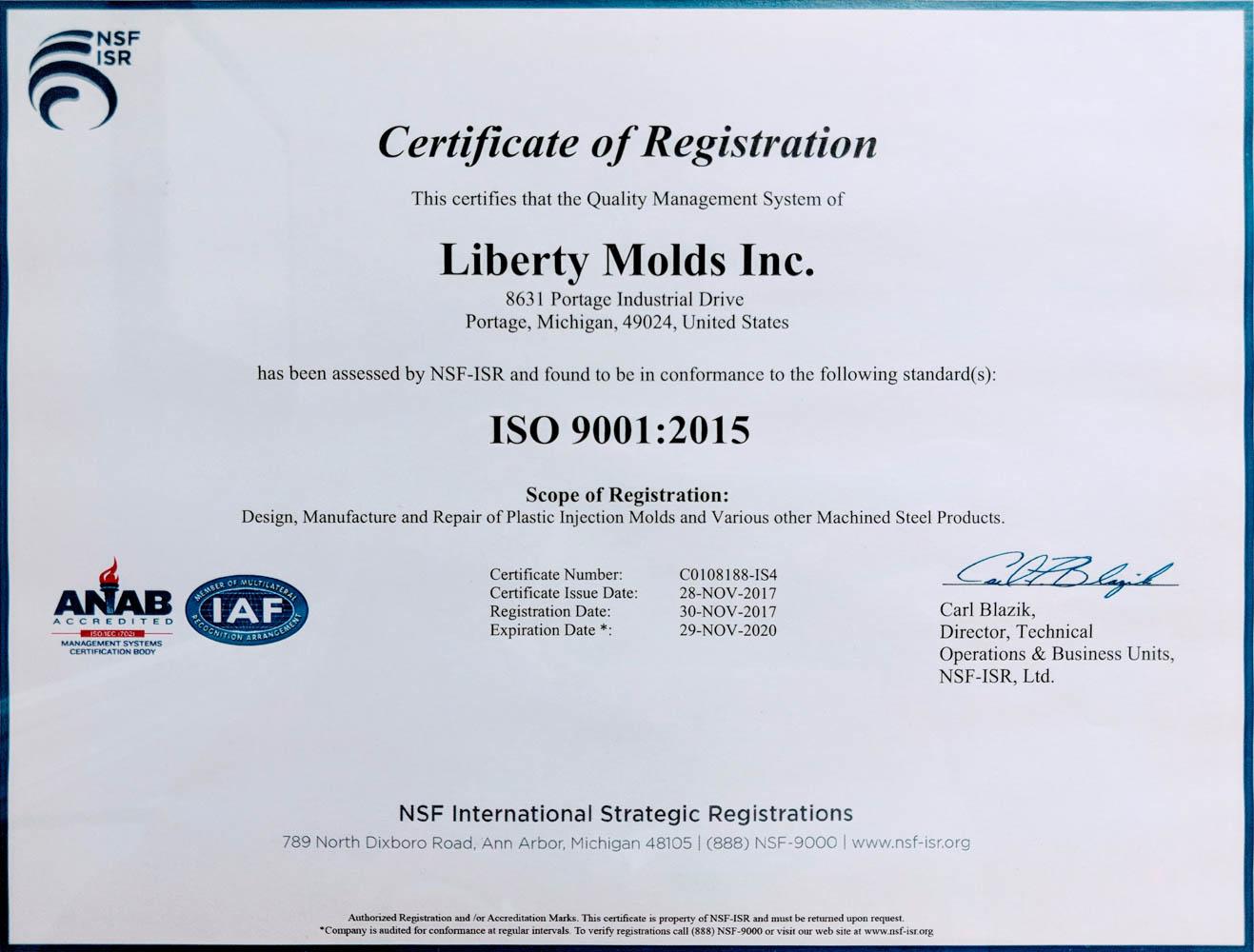

The International Organization for Standardization (ISO) is not a certifying agency, but it creates the quality standards which must then be verified by an independent third party. Liberty Molds has been certified to ISO 9001:2015 by an ANAB-accredited registrar.

Studies have shown, companies that utilize ISO 9001 as their standard for quality have key performance measures in place to continually drive improvement. By assuring the quality our products against international standards, we can then focus on customer service and delivery.

But in order to achieve this certification, Liberty Molds has undergone a rigorous audit. For instance, this latest standard (ISO 9001-2015) emphasizes implementation of the “plan-do-check-act” (PDCA) cycle on all levels of our organization. (PDCA is four-step management tool for the continuous improvement of processes and products.)

But in order to achieve this certification, Liberty Molds has undergone a rigorous audit. For instance, this latest standard (ISO 9001-2015) emphasizes implementation of the “plan-do-check-act” (PDCA) cycle on all levels of our organization. (PDCA is four-step management tool for the continuous improvement of processes and products.)

We maintain these ISO 9001 standards to ensure all of our processes and proposed improvements are customer-focused, so we can continue to deliver a superior product. We establish systems and protocols to help reduce costs, minimize waste, increase productivity, eliminate errors, and dramatically improve overall quality.

All company processes and procedures have been documented in our published quality manuals.

Quality Integration

Quality is integrated throughout our engineering and mold manufacturing operations. Three-D mold models flow between departments so that they can be designed, produced and tested in the most efficient manner possible.

This quality integration process ensures that we develop inspection procedures that are consistent with your needs. Every Liberty Molds employee is dedicated to quality, continual improvement and customer satisfaction.

Details Count

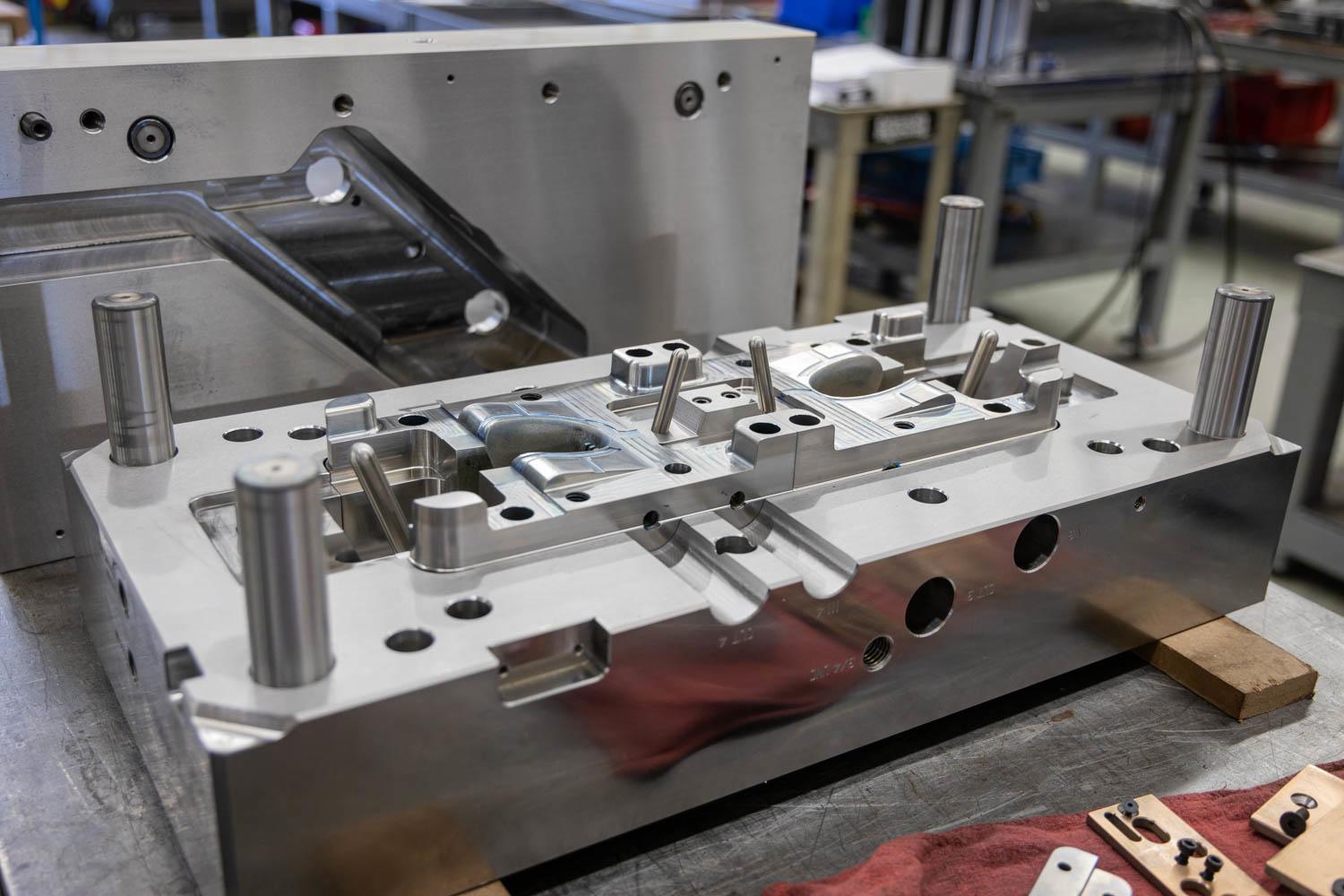

The mold makers at Liberty Molds pride themselves on building high-precision, complex plastic injection molds. We know it’s the details that make the difference. Which is why even the smallest detail won’t escape the watchful eyes of our experienced team of mold making professionals.

Liberty Molds builds quality plastic injection molds designed and manufactured to ensure consistent, accurate parts, year after year for the life of the mold.

Two-shot mold inserts. Roll your mouse over the image to see a closeup of our careful venting.

Two-shot mold inserts. Roll your mouse over the image to see a closeup of our careful venting.

Various in-part markings may be proud or hidden, on inside or show surfaces

Various in-part markings may be proud or hidden, on inside or show surfaces

Mold components are laser marked or engraved with part numbers for easy service and support

Mold components are laser marked or engraved with part numbers for easy service and support

ISO 9001:2015 Certified